The harmful effects of microplastic pollution on the environment and human health are a growing concern that is being addressed with recycling solutions driven by the plastic industry itself, as well as municipal Wastewater Treatment Plants (WWTPs), and other organizations worldwide. Monitoring microplastics in plastic recycling facilities is crucial in understanding how different polymers behave throughout the recycling process to mitigate the risk of those plastics being introduced to the natural ecosystem. And in WWTPs, monitoring microplastic contamination is important to ensure reclaimed water is pure and safe before it is returned to rivers, lakes, and oceans.

Flow Imaging Microscopy (FIM) is a valuable approach that plastic recycling facilities and WWTPs are using to monitor microplastics in their workflows. FIM captures high-resolution digital images of individual microplastic particles and calculates an immediate array of relevant particle property metrics such as size, shape, morphology, and light intensity values. Running an FIM sample to produce data is quick and easy, allowing users to run numerous samples in a short period of time and determine optimal protocols for microplastic particle management.

Our application note, Monitoring Microplastics Using Flow Imaging Microscopy, describes the advantages and limitations of a variety of microplastic monitoring techniques and presents two case studies that introduce FIM as a high-throughput tool for microplastics analysis. The case studies use FlowCam, a flow imaging microscope, to analyze morphological differences between polymer types or changes in morphology within a polymer type throughout the recycling or treatment workflow. These observations can provide valuable information about process strategies.

Process Monitoring in Plastic Recycling Facilities

Since most plastic materials are not manufactured with recyclability in mind, robust technologies are needed to track yields and assess the potential for repurposing materials into new plastic-based products. When recyclable plastics such as packaging films, plastic bags, water bottles, food trays, and more are sent to waste-sorting facilities, they are separated by polymer type and undergo a series of cleaning stages including intense washing and contamination removal steps. Recycling facilities spend a lot of money and use huge amounts of water (around 25 cubic meters of water per hour). To optimize efficiency, and save both time and resources, these facilities need reliable, high-throughput monitoring systems to assess workflow impacts on recycling yield. More importantly, since various polymer types respond differently to process conditions, dependable washwater characterization is required to mitigate the risk of microplastics entering natural ecosystems.

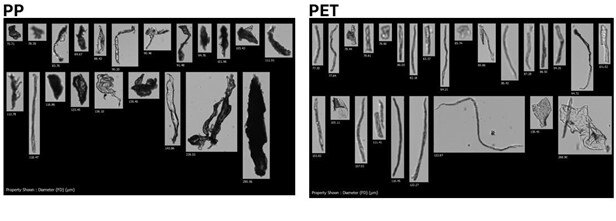

In the first of two case studies, samples of polypropylene (PP) and polyethylene terephthalate (PET) wash water were taken from different stages of a recycling facility workflow and analyzed with FlowCam. When particle images from the PP and PET washwater samples were compared, plant operators were able to use these morphological differences and their knowledge of the source materials to determine which washing steps needed optimization.

Assessing Membrane-Based Filtration Processes in Wastewater Treatment Plants

As wastewater from homes, businesses, and stormwater runoff drains through sewer systems and is delivered to wastewater treatment plants, microplastics are carried along as stealthy, but prominent pollutants. WWTPs apply treatments to this water to 1) screen and remove large plastic debris, 2) chemically neutralize small microplastics causing them to clump together and settle out, and 3) remove even smaller microplastics through membrane filtration. Despite the progressive mechanical and chemical treatments that wastewater undergoes, microplastics are often not fully removed. Like plastic recycling facilities, high-throughput and reliable monitoring technology is needed to assess the overall effectiveness of WWTP processes and to ensure the discharge of microplastics in treated effluent is minimal.

Our second case study provides an overview of a recent publication in Separation and Purification Technology (Y. Hyeon et al., 2024), where FlowCam was used to assess the effect microplastic size and shape had on membrane-filtration effectiveness in treatment of wastewater.

Sample wastewater solutions containing either polyethylene (PE), polyamide (PA), or a mix of PE and PA microplastics were analyzed both pre- and post-membrane filtration. The researchers used the FlowCam data to determine that membrane filtration was more effective on PE microplastic particles, whereas PA particles tended to either pass through or clog the filter.

PE PA

FlowCam Provides an Efficient Tool for Monitoring Microplastics

These studies illustrate how Flow Imaging Microscopy with FlowCam enables efficient characterization of microplastic particles in industrial workflows. Integrating FlowCam as a diagnostic tool for monitoring various stages of microplastic recycling and wastewater treatment processes can yield a deeper understanding of microplastic behavior and inform improvement strategies from which we all stand to benefit.

These studies illustrate how Flow Imaging Microscopy with FlowCam enables efficient characterization of microplastic particles in industrial workflows. Integrating FlowCam as a diagnostic tool for monitoring various stages of microplastic recycling and wastewater treatment processes can yield a deeper understanding of microplastic behavior and inform improvement strategies from which we all stand to benefit.

Download our application note to learn about these techniques in detail and see the full results of the case studies:

"Monitoring Microplastics Using Flow Imaging Microscopy"

Download the Application Note

Ready to learn more?