Flow Imaging Microscopy is a fast and automated method for obtaining highly resolved digital images of microscopic particles in a flowing liquid. With this technique you can very quickly learn about the size, count, shape, and identity of the particles in your sample.

The Scientific Origin of Flow Imaging Microscopy

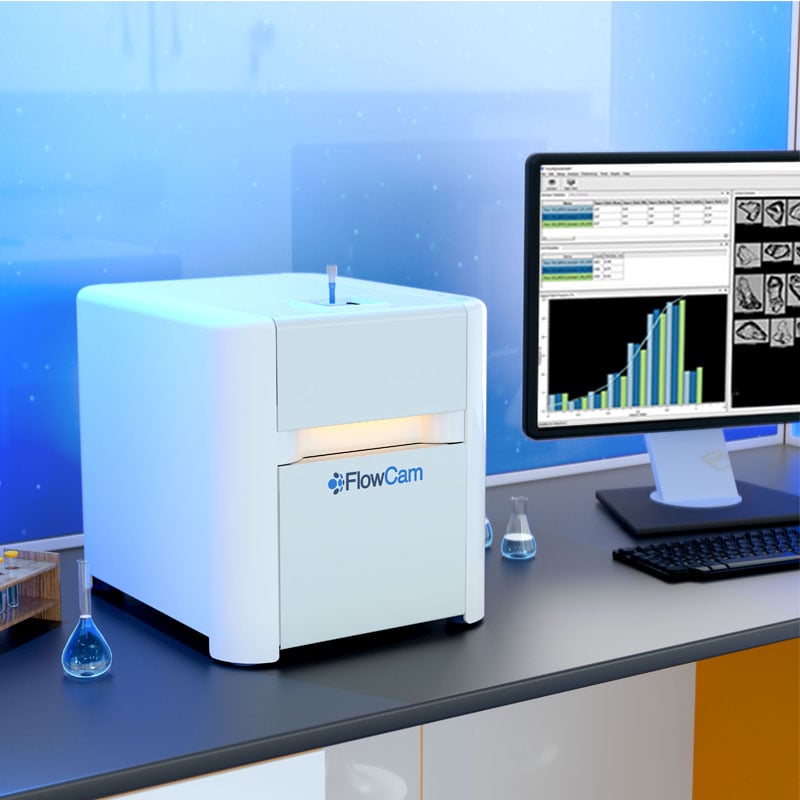

Flow Imaging Microscopy began as a novel concept when the first flow imaging microscope—FlowCam—was developed at Bigelow Laboratory for Ocean Sciences in Boothbay Harbor, Maine. The tools available at the time—a microscope for identifying plankton and a flow cytometer for counting them—were time-consuming and labor-intensive. As a result, scientists at Bigelow set out to develop a more efficient method.

Their FlowCam design combined the benefits of a flow cytometer and a microscope in a single instrument. A sample of ocean water could be introduced into the system, and particles would be automatically, digitally imaged and analyzed.

How Flow Imaging Microscopy is Used Today

Today, FlowCam is an essential tool in particle characterization labs across a broad range of biologics and materials applications, where understanding the size, shape, and morphology of particles in solution is critical.:

- Aquatic Research and Water Quality Monitoring: the study of microbial life in the world’s marine and freshwater bodies to understand key processes driving these ecosystems

- Biopharmaceutical Applications: characterization of biopharmaceutical aggregates and other subvisible particles in parenteral drugs to evaluate the stability of formulations

- Cell Therapy Quality Control: supporting drug product analysis to advance cell therapies.

- Stability & Quality of Gene Therapies: providing rigorous characterization of therapeutics targeting cancer, infectious diseases, and genetic disorders to ensure safety and efficacy.

- Food and beverage: quality control of food ingredients, where particle shape can affect taste and texture

- Materials Characterization: Perform materials characterization testing in accordance with compliance and cleanliness standards.

How Flow Imaging Microscopy Works?

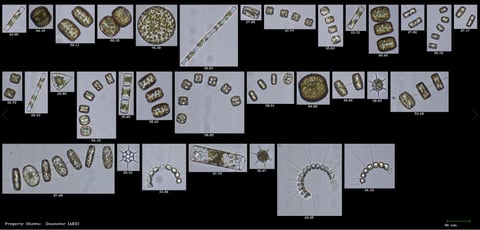

FlowCam streamlines the workflow for imaging particle analysis! A sample containing particles is injected into a flow cell, where it flows through a path positioned between a light source and a magnifying objective in front of a digital camera. As the sample passes by, the camera automatically captures images of up to 50,000 particles per minute.

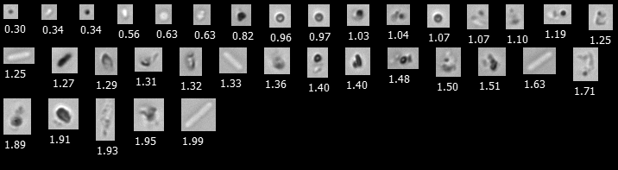

In real time, the VisualSpreadsheet software extracts single-particle images from the camera images. It compiles a variety of basic measurements, such as particle count, diameter, volume, and aspect ratio, as well as more advanced morphology measurements, such as circularity, elongation, and perimeter. Other particle characteristics include intensity, transparency, and color. Using VisualSpreadsheet, you can readily sort, filter, classify, and display your data analysis in various formats.

One Advantage of Flow Imaging Microscopy: Direct Particle Measurements

One of the key advantages of flow imaging microscopy with FlowCam is that particle measurements are calculated directly from an image of the particle. Since flow imaging microscopy is designed with fixed optics at known magnifications, distance measurements in the image can be directly converted to real-world measurements on the object. Flow imaging systems do not have to make any assumptions about a particle’s size and shape because they measure multiple particle properties directly from an image.

Other particle analysis systems, such as light obscuration, laser diffraction, and light scattering, require assumptions about the particle's physical dimensions. These techniques measure a signal proportional to a physical dimension and convert it into a value representing the number of particles and the corresponding particle-size distribution in the sample. In addition, many of these analytical techniques only measure ensemble (bulk) properties, i.e., the properties of the overall population distribution.

The ultimate benefit of performing flow imaging microscopy with a FlowCam imaging system is that you can visualize single particles and calculate desired sample properties based directly on individual particle images.

Want to dig deeper into flow imaging microscopy, including detailed FlowCam applications and use cases?

Download our eBook on Flow Imaging Microscopy to learn more.

Would FlowCam work for me?

Send us a brief description of your application, and we’ll be happy to discuss how FlowCam can help you accurately characterize your particles!

Click here to describe your application