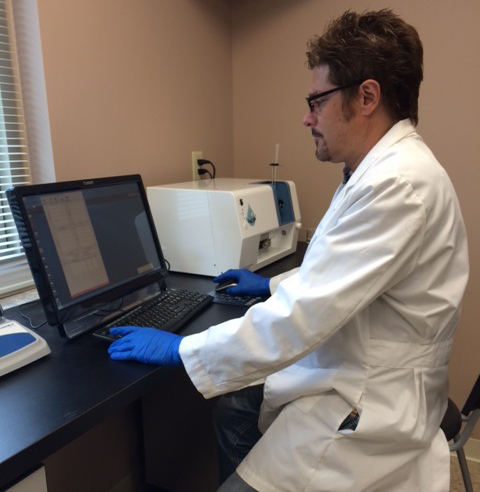

AB BioTechnologies, now Labyrinth Biopharma, is a privately held laboratory offering pharmaceutical contract services in Bloomington, Indiana. Founder and CEO Dr. Jeff Schwegman has extensive experience in formulation development, lyophilization (freeze-drying) cycle development and optimization, thermal characterization, and education and training in the development of injectable drug products.

AB BioTechnologies customers need help with drug and diagnostic products in various stages of development. They can require assistance with a wide variety of problems ranging from, "We just discovered a molecule to treat a disease. What do we do with it?" to, "We’ve got something developed and we're having problems getting it just right."

Sometimes these companies are very small and consist of just a few people. If they don't have scientists on staff they contract AB BioTechnologies to do the bulk of the development work. "We'll subject formulations to stress factors like freezing and freeze drying and then we'll measure and characterize the initial solution to get a baseline," says Dr. Schwegman. "We add stabilizing excipients, then we'll freeze dry it again and reexamine the sample particles to see if we're generating any aggregates."

When AB Biotechnologies completes a project for a customer they hand them a formulation or a lyophilization cycle and manufacturing process that they can take to a licensed manufacturer to produce their product.

The Challenge

In the protein therapeutic drugs that AB Technologies works with, translucent protein aggregates can easily go undetected. These aggregates and other unwanted particulates in the drug products have the potential to disrupt the safety and/or efficacy of the drugs, so identifying and enumerating them is a crucial step in the development process.

Traditional particle analysis methods, including light obscuration (LO), USP's compendial analytical method for particle analysis in the development of biotherapeutics, can undersize or miss transparent and translucent particles entirely.

The Solution

AB BioTechnologies uses and recommends laboratory equipment from many vendors, but Dr. Schwegman says that the one of the most essential instruments in his lab for detecting protein aggregates is FlowCam. FlowCam uses flow imaging microscopy (FIM) technology to capture high-resolution images of thousands of particles per minute.

One of the key advantages of FIM with FlowCam is that particle measurements are calculated directly from an image of the particle. Unlike LO, flow imaging systems do not have to make any assumptions about a particle’s size and shape because they measure multiple particle properties directly from an image.

When Dr. Schwegman and his team are working on formulations that have the potential to denature and aggregate they do an excipient screen with FlowCam. FlowCam's high-throughput imaging capabilities allow Dr. Schwegman to characterize particulates efficiently and with a high level of accuracy. "Image quality is extremely important when characterizing protein aggregates," explained Dr. Schwegman. “We need to be able to differentiate them from silicone oil and other contaminants in drug formulations early in the process.”

The Results

With VisualSpreadsheet software, FlowCam can record over 40 different measurements per particle and can capture particle images at up to 100 frames per second enabling biopharma development organizations like AB BioTechnologies to quickly get the answers they need to drive formulation development.

“Data is one thing, but having instantaneous information is another,” says Dr. Schwegman. “The FlowCam is an integral part of our screening process.”

For example, if they need to screen a monoclonal antibody formulation, they will freeze-dry it and see if aggregated particulates show up using FlowCam. If aggregated particulates are present, they will need to blend in stabilizers. They will repeat the process of blending and running samples to help shape the formulation.

AB Biotechnologies is a relatively small company, but it has grown by finding the right technologies for its lab that help it service more customers more quickly and by offering the best possible solutions. "If FlowCam wasn't part of our lab I'd have to contract out if I wanted to test for protein aggregates,” says Dr. Schwegman. “It just made sense to bring it in-house."

AB Biotechnologies has experience working with many different formulation types including injectable drug products, lyophilized powders, emulsions, and suspensions. With their development services, a complete, optimized cycle can be designed in less than 30 days. Additionally, Dr. Schwegman provides training on product formulation and lyophilization within the pharmaceutical and diagnostic industries.

To learn more about the capabilities of FlowCam for biotherapeutic development, download our eBook, The Ultimate Guide to Flow Imaging Microscopy: