Particles come in many shapes and sizes. Analyzing particles in food ingredients and correctly characterizing them is important because they can greatly affect the taste, appearance, stability, and processability of the final product. CP Kelco, a leading producer of specialty hydrocolloids based in San Diego, manufactures a variety of texturizing and stabilizing ingredients for food processors. Flow Imaging Microscopy (FIM) allows them to quickly and easily detect particle variations and ensure top quality products.

He’s called the fixer.

Many companies have one. He may be the ace maintenance mechanic who gets the call when a machine goes down unexpectedly. Or maybe he’s the process engineer who invariably is the one who figures out why a batch failed to meet specifications.

At CP Kelco, it’s Ross Clark, Distinguished Research Fellow. He’s the fixer. For the San Diego, California-based supplier, Clark is assigned the tough questions, as well as those he poses himself. Flourishing in a capacious job title that many a scientist would envy, Clark is free to pursue answers to the most vexing challenges, to follow hunches and see where the trail leads.

In fact, it was a hunch about the behavior of particles in movement in a customer’s powder eductor that most recently caught Clark’s interest.

For the materials in question, operators had already effectively adjusted airflow to resolve occasional powder-flow blockages. Meeting product quality specifications was never at risk. No one even thought there was a problem. Yet Clark suspected that particle shape variation from batch to batch was causing some amount of variability.

To compare individual particle shapes, Clark could study laboratory samples using a microscope. It would take hours to prepare samples, set up slides and measure any particles found, all the while knowing that some particles would be hidden by others and that they would be squeezed into shapes and sizes that differed from how they were formulated.

Substantial reliance on human judgment also troubled Clark. “Manual microscopy was just too cumbersome and slow. It was difficult to see more than a handful of particles, certainly not enough to get a statistically significant sample,” Clark says. At a rheology trade fair he found a way to improve the process.

“When I saw the FlowCam®, I thought, ‘this is so cool!’ Now, I can get 10,000 images of individual particle in less than a minute.”

The Tools of a Detective

The FlowCam flow imaging microscope detects the presence of particles and cells in a sample, takes a high-resolution digital image of each one and saves the images and measurement data for review and analysis. Combining the high speed of flow cytometers and the visual capabilities of microscopy, the system images thousands of particles in seconds while measuring up to 30 different particle properties, from basic morphological measurements such as area, length, width, diameter, volume (ESD) and aspect ratio to advanced types such as circle fit, elongation, perimeter and roughness.

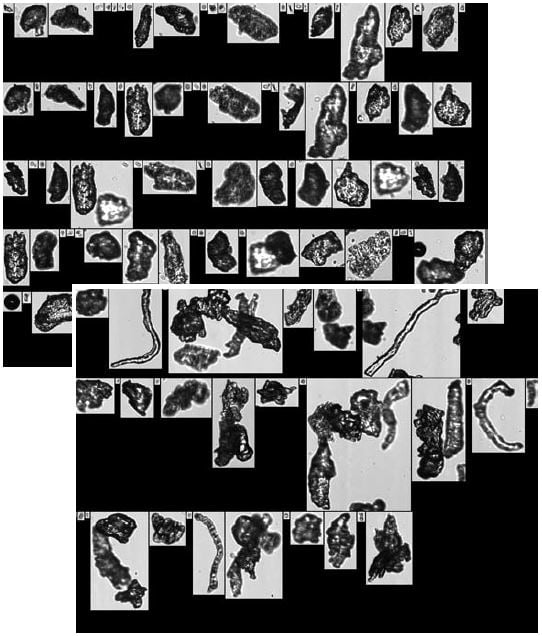

Using the FlowCam, Clark quickly proved correct his hunch about particle morphology affecting powder flow. Though the product met all required specifications, the screening method used to measure particle size — and that also is used throughout the dry products industry — was unable to recognize the shape of individual particles, allowing the product to meet the size specification despite variations in shape.

This is significant because pneumatically conveyed particles of different shapes flow differently. A spherical or oddly shaped particle, for example, moves differently in an airstream than a flat or square particle such as a crystal. “Most people just don’t know enough about how particle morphology affects product performance or flow characteristics to ask the question,” Clark says. “Seeing digital images of individual particles on the FlowCam provided the documentation I needed to prove what was happening.”

Further Steps Taken

Clark then used the FlowCam to compare the size and shape of xanthan gum samples produced at two different plants.

Batches from both plants met screen-size specifications and appeared identical, yet the customer experienced performance variations from one batch to the next. By imaging thousands of particles supplied from each location, minor differences in particle size distribution were revealed, documented and addressed. While mesh screens set a ceiling on the particle size they cannot account for very small particles and dust.

“The FlowCam has advanced measurement technology beyond what people are used to measuring,” Clark says, “so the metrics people have traditionally used to assess quality are probably outdated for most manufacturers, especially for those offering products where particle characterization is as important as it is for gums.”

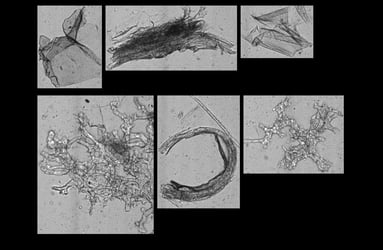

Pictured above: xanthan gum and cellulose gum particles imaged by the FlowCam

Xanthan gum, guar gum, pectin, carrageenan, cellulose gum and other CP Kelco products are used to impart thickening, stabilizing, suspending, texturizing and other properties to foods, beverages, chemicals, pharmaceuticals and personal care products.

Careful formulation, production, and packaging are required to meet dispersability, hydration rate, powder flow and other key performance characteristics. Yet all of these are affected by individual particle size and shape.

Similarly, agglomerated particles and blends such as pectin blended with sugar — or xanthan gum blended with guar gum — demand compatible particle sizes to ensure they remain locked together. If they become separated, required characteristics aren’t delivered. “The worst part of a particle size or shape issue is that it probably never occurs to the processor to check gum particle size or shape or that of any other ingredient. Instead, the recipe or the machinery are blamed,” says Clark.

Making It Good Practice

Clark typically shares particle images with customers, distributors and colleagues all over the world via email. Seeing actual images on screen after years of working with these products in formulation, manufacturing or packaging projects causes quite a reaction.

To ready samples for a run through the FlowCam, Clark devised a procedure that suspends product within a clear paste, ensuring each particle remains still, yet visible, to the flow cell for detection and imaging. “Every product is different and every problem I study is different. I tried a number of approaches, using different magnifications, before determining the most effective way to get the sharpest product images,” says Clark.

“Most particle analyzers base their measurements on an idealized model where every particle must be considered a round sphere,” says Clark. “The FlowCam ... bases its measurements on the actual size and shape of the particle.”

Originally published in Processing Magazine

Learn more!

Download our eBook, The Ultimate Guide to Flow Imaging Microscopy, which explores a variety of methods for analyzing particles and discusses issues associated with particle analysis.