We talk a lot about FlowCam for biopharmaceutical and aquatic applications. The high-quality images resulting in detailed morphologic data are ideally suited for these applications - to discriminate among different kinds of particles and cells like aggregates, contaminants, and other outliers. VisualSpreadsheet provides an easy-to-use method to sort and identify particle images based on their shape and 40+ attributes.

Beyond standard particle sizing and counting, FlowCam is also an exceptional tool for performing materials testing in accordance with compliance and cleanliness standards. Customers are using FlowCam across a broad range of applications to compare advanced particle shape data between different lots and production steps to detect process flaws and improve product performance, quality, and safety. Keep reading to learn more about the many different kinds of materials FlowCam can image and analyze.

Wash Water and Cleanliness Testing

Dirt, fibers, and debris always seem to make their way into finished components - especially in aerospace, automotive, electronic, and hydraulic systems. Water used to wash devices or components after manufacturing is analyzed to determine what and how many particles are present. Traces of fibers, metals, and plastics that remain from the manufacturing process may cause product failures. FlowCam makes it easy to sort and filter particle data and build libraries to automatically quantify and characterize each particle type.

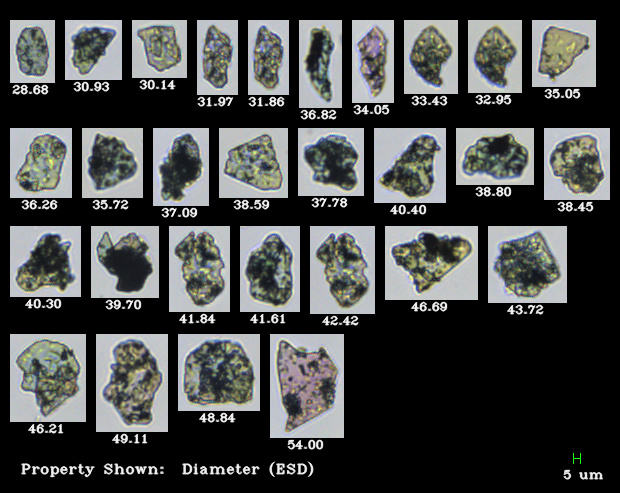

Characterization of Superabrasives

Superabrasives, such as micronized diamonds and cubic boron nitride (CBN), are used extensively in applications for cutting, grinding, and drilling hard materials. Particle size and shape play an important role in the durability and effectiveness of these superabrasive grinding tools. As it turns out, shape uniformity is a critical quality attribute where particles with smooth and rounded edges are most effective! FlowCam provides particle morphology analysis and can report on what percentage of particles meet uniformity standards around circularity and aspect ratio.

Fiber Analysis

Who knew that geometry would play such a crucial role in the performance of fibers in different applications? Shape factors that influence performance include length, width, and curl. Despite the importance of fiber geometry, many conventional particle sizing measurements struggle to accurately capture the morphology of these particles.

FlowCam excels in this process with integrated fiber morphology parameters that include geodesic length, geodesic thickness, fiber straightness, and fiber curl. Using these advanced measurements, FlowCam provides more accurate and reliable data than volumetric-based methods and offers significant time-savings over manual microscopy.

Crop and Soil Sciences

FlowCam aids in assessing seed viability and studying plant development defects. There is an interesting cross-over application with the pharmaceutical industry when FlowCam is used to analyze the shape and intactness of pollen shell capsules in drug delivery systems. FlowCam is also a valuable tool in agriculture applications for identifying and monitoring soil microbes, mites, forest litter invertebrates, and nematodes contributing to crop health.

Microencapsulation Process Analysis

FlowCam is essential for microencapsulation research and quality control across various industries including food, beverage, pharmaceutical, cosmetics, and fragrances. It provides unique insights into the microencapsulation process by dynamically monitoring capsule formation over time, allowing for optimization and clean coacervate formation.

Food and Beverage Particle Characterization

Ingredients play a vital role in the food and beverage industry. Taste and texture are important quality attributes determined by particle size and shape. Leveraging flow imaging microscopy, you can identify diverse particle types within a mixed composition to achieve quality standards and pinpoint operational inefficiencies. With its high-throughput capabilities, FlowCam is perfect for identifying variations in particle size, shape, and structure, streamlining the quality control process.

Printer Toner Quality Assurance

Did you know that the size and shape of printer toner particles can considerably impact the image resolution and efficiency of a printer's output? The uniformity of these particles also impacts the distribution of charge they carry, which can ultimately influence the overall quality of images. Utilizing FlowCam for image characterization can aid in identifying the size, shape, circularity, and material consistency of printer toner particles throughout the production process and lead to overall improved quality.

Have we piqued your interest in learning more about FlowCam for materials characterization? Download our materials applications brochure and let us know what you think.