Ingredients play a pivotal role in every aspect of the food and beverage industry, from the initial stages of product development to the final quality assurance checks. Flow imaging microscopy is a revolutionary advancement that empowers manufacturers to meticulously isolate and analyze different particle types from a complex, heterogeneous mixture. This capability is essential for ensuring the highest quality standards and for the early detection of any process flaws that could compromise the integrity of the final product.

FlowCam, a state-of-the-art, high-throughput analysis tool, offers unparalleled efficiency in this regard. It is designed to detect even the slightest variations in particle size, morphology, and texture, which are critical parameters in maintaining consistent food quality control. By providing detailed insights into these variations, FlowCam facilitates a more streamlined and effective approach to managing and optimizing the quality of food and beverage products.

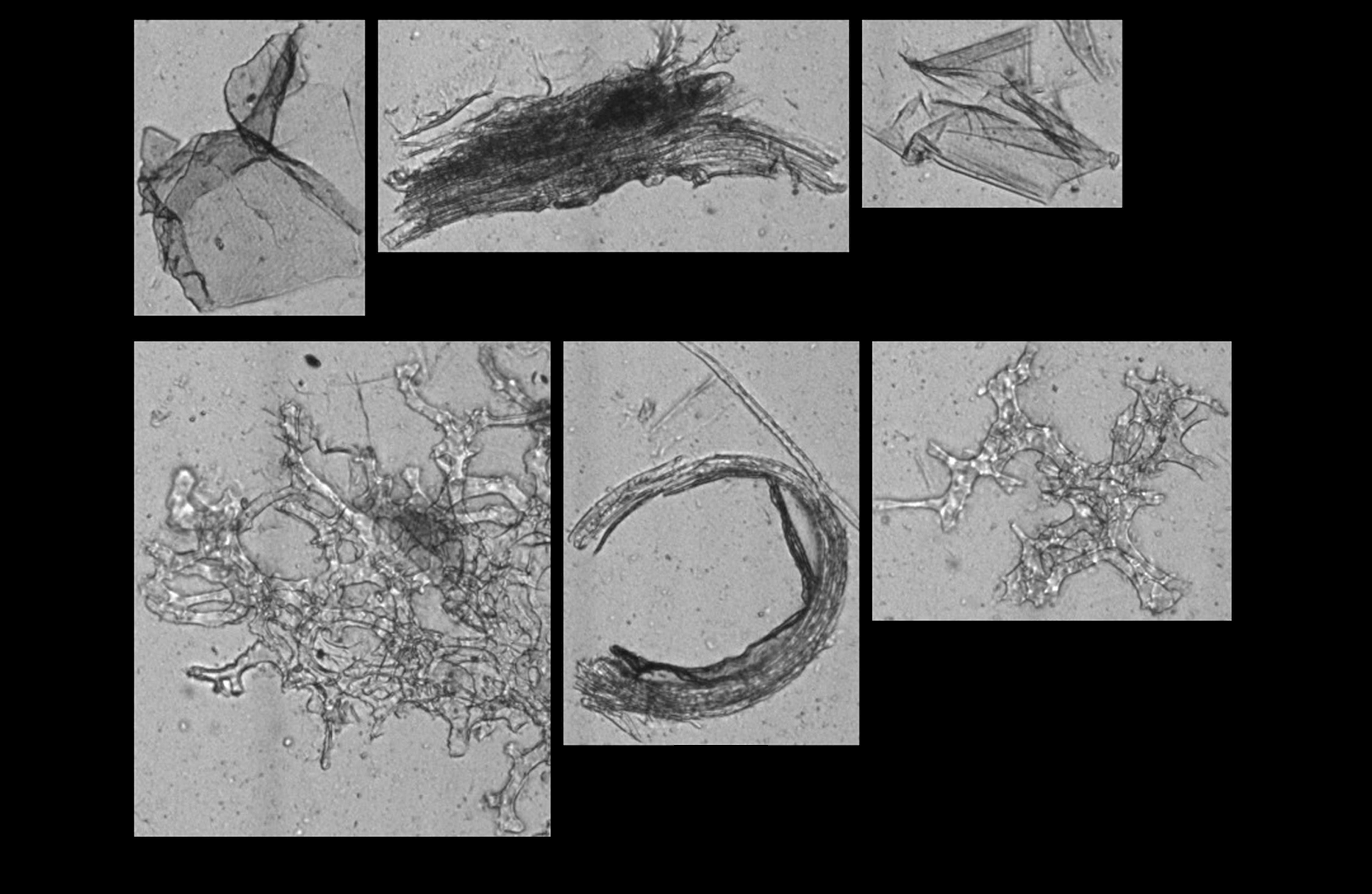

It's important to be able to see images of different particle types when considering how to characterize your subvisible particles for food and beverage production.

Your ingredients are vital in every aspect of the food and beverage industry, serving as the foundation for creating and refining products. From the initial stages of formulation research, where the precise combination of ingredients is determined to achieve the desired flavor, texture, and nutritional profile, to the rigorous processes of production quality control, where consistency and safety are paramount, the role of ingredients cannot be overstated. The unique capabilities of FlowCam are instrumental in this context, as it provides comprehensive information on particle size and shape (morphology). This advanced technology allows you to meticulously isolate and analyze different particle types from a complex, heterogeneous mixture, ensuring that each component meets the stringent standards required for high-quality food and beverage products.

In a practical application, the FlowCam was utilized to image the fruit juice sample mentioned above. This particular beverage manufacturer was keenly interested in characterizing the size, shape, and concentration of pulp particles within their concentrate mixture. By doing so, they could ensure that the final product met their specific quality criteria and consumer expectations.

The advantage of employing a system that provides visual images of your particles instead of relying solely on non-imaging technologies like Light Obscuration is significant. With the ability to see detailed images of the particles, you can confidently verify that the contents of your products align with your intended formulation. This visual confirmation not only ensures the quality and consistency of your products but also allows for the early detection of any process flaws, enabling you to address potential issues swiftly and maintain the integrity of your production processes.