Hydraulic fluids, lubrication oils, and fuel need to be monitored for cleanliness according to standards such as ISO 4406 or NAS 1638. Optical microscopy is "considered by many to be the most reliable and accurate method of particle counting"; however, optical microscopy is tedious and time-consuming. Other, more preferred methods include automated particle counters that use either pore blockage or laser detection for particle analysis. However, these methods are blind and are unable to differentiate between detritus, air bubbles, water droplets, and other contaminants that may have similar size and shape. While these laser-based and shadow-based solutions are good at counting particles, they are unable to tell you whether your particle count is comprised mostly of air bubbles or detritus.

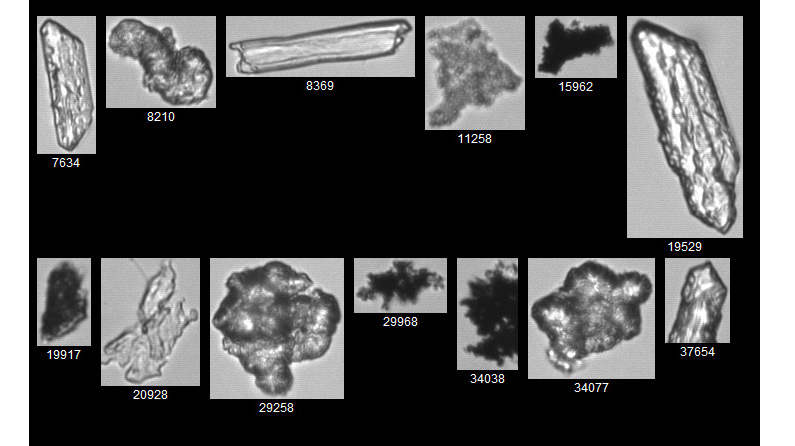

The FlowCam imaging particle analyzer counts and images the particles within each sample. Using VisualSpreadsheet®, the FlowCam's accompanying analysis software, the FlowCam can differentiate between air, water, and other contaminants using morphological characteristics measured in each particle image. It can then report particle counts and concentrations binned by size range according to the specified standard.

Within a few minutes, you will get concentration data (particles/mL or PPM) and summary statistics on various morphological parameters.

FlowCam enables monitoring of all your fluids to ensure they meet your quality specifications and industry-accepted standards.

Learn more about how the FlowCam imaging particle analyzer helped differentiate oil from solids in a recently published skim tank analysis study by Baker Hughes.