A study by Baker Hughes demonstrates how FlowCam® imaging particle analysis technology is a more informative method than spectrophotometry in evaluating the demulsification of produced water. Produced water generated during oil extraction is held in skim tanks and treated with water clarifiers or demulsifiers. Reverse emulsion breakers (REBs) coalesce the oil into larger molecules to be skimmed or removed from the produced water. The efficacy of REBs and other water clarifiers on produced water is important because oil extraction companies must meet water quality environmental regulations before releasing produced water back into the environment, or they require a low oil content if the water is to be reused in the extraction process.

The Problem

The oil content in water is typically analyzed using a spectrophotometer. However, this method only quantifies the oil; it does not measure oil droplet size, calculate size distribution, or provide information on the behavior of oil droplets in the water during the reverse emulsion process.

The Study's Objective

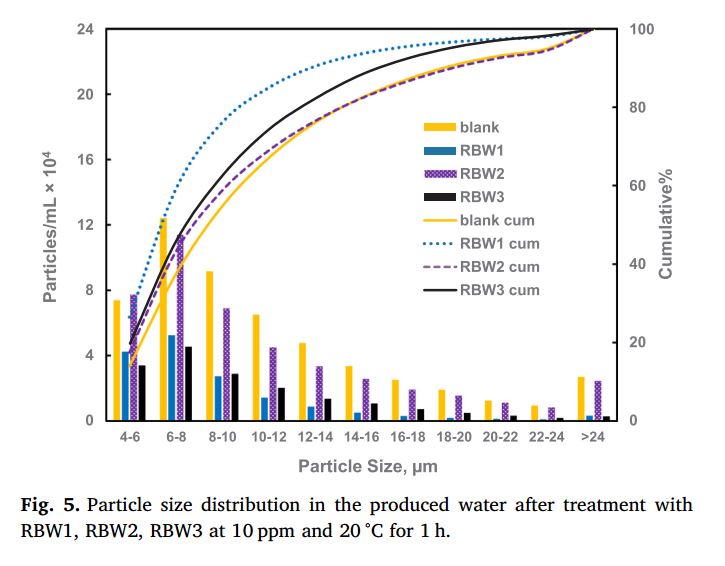

Feng et al. evaluated the efficacy of three different REBs for oil-in-water clarification using FlowCam technology in this study. Oil droplet size, oil/solids concentration, and particle size distribution were measured in the produced water before and after REB treatment at 1-hour and 4-hour intervals. The FlowCam calculated the oil and solids concentrations in each sample.

Methodology

The morphologies of the particles, as imaged by FlowCam, were used to classify them. Spherical particles were classified as oil droplets and non-spherical particles were classified as solids or solid/oil aggregates. Particle size and concentration as a function of time could be quantified using the FlowCam-generated particle size distribution, which enabled Feng et al. to study the deoiling process and mechanism closely.

Results

Feng et al. found that REB-treated produced water had substantially fewer oil droplets of all sizes than untreated water. The most effective REB helped remove oil droplets of all sizes and completely removed larger ones. Increased treatment time also improved the REB efficacy as more oil droplets were given time to coalesce, larger droplets moved to the water surface, and only small oil droplets were left behind. (Image credit Feng et al., 2018).

Conclusions

Feng et al. found that the FlowCam imaging particle analysis technology was a successful technology to analyze oil in produced water. It is "quick and provides information on the oil/solids content, oil droplets size and size distribution using a small amount of sample. The analysis helps to understand the behavior and the performance of REBs in water clarification."

The FlowCam has proven successful in many stages of the oil extraction process, from drilling mud material characterization and frac proppant analysis to hydraulic fluid monitoring and catfines analysis.

Citation:

Feng, X., Fakunle, D., Osness, K., Khan, G., Sartori, L. (2018). Oil in water characterization by dynamic optical fluid imaging technology. Fuel, 234, 700-706. doi: 10.1016/j.fuel.2018.07.064