High-performance liquid chromatography (HPLC) is a sophisticated and widely utilized technique in the field of analytical chemistry. It is specifically designed to separate, identify, and quantify each individual component present in a complex mixture. This method is essential for analyzing compounds in various industries, including pharmaceuticals, environmental monitoring, and food safety. The process relies on the use of pumps that efficiently pass a pressurized liquid solvent, which contains the sample mixture, through a column packed with a solid adsorbent material. This column acts as the stationary phase, while the liquid solvent serves as the mobile phase. Each component within the sample mixture interacts slightly differently with the adsorbent material due to variations in their chemical properties, such as polarity and molecular size. These interactions result in different flow rates for the various components, ultimately separating them as they exit the column. The separated components can then be detected and quantified, providing valuable information about the composition of the original mixture.

In column chromatography, the elution rate of different components in a mobile phase is significantly influenced by the size and shape of the particles that make up the stationary phase. This is because the interaction between the mobile and stationary phases is largely determined by how the particles are packed and their surface characteristics. When the stationary phase consists of uniform particles, the precision of the elution rate is greatly enhanced. Uniform particles ensure a consistent flow path for the mobile phase, reducing variability and improving the separation efficiency of the chromatography process. This uniformity minimizes the chances of channeling or uneven flow, which can lead to inaccurate results and poor resolution of the components being analyzed.

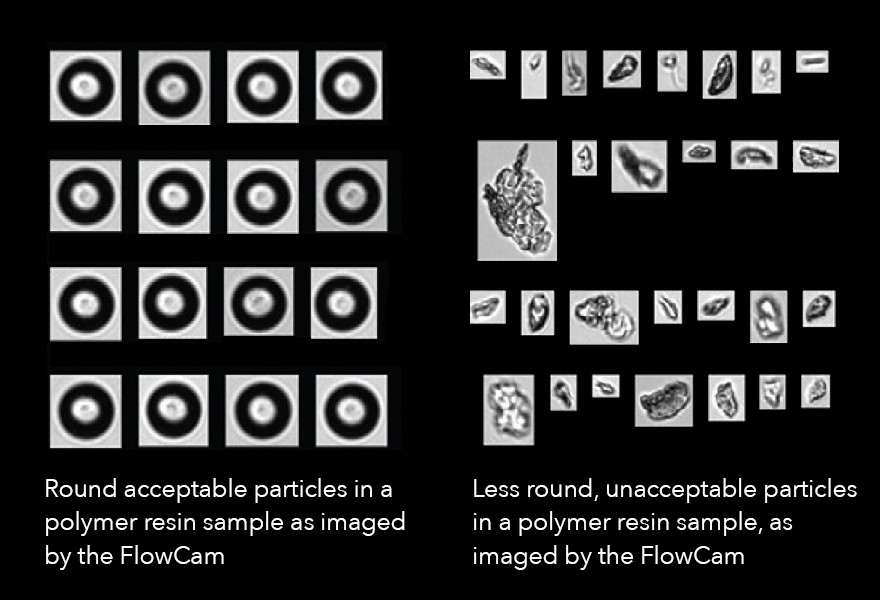

FlowCam is an advanced analytical tool that provides critical information about the size and shape of particles, which is essential for achieving tighter control over column density. By offering detailed insights into the physical characteristics of the particles, FlowCam enables better management of column performance. This enhanced control is crucial for optimizing the separation process, as it allows for adjustments that can improve the accuracy and reliability of the results. Additionally, FlowCam is instrumental in identifying and tracing damaged or non-spherical particles often present in lots of column packing material. These irregular particles can disrupt the uniformity of the stationary phase, leading to inconsistencies in the chromatography process. By detecting these anomalies, FlowCam helps ensure that only high-quality packing materials are used, thereby maintaining the integrity and efficiency of the chromatographic separation.