Challenges in Accurate Fiber Characterization

Fiber geometry plays a critical role in the performance of fibers across a wide range of applications. Key shape factors that influence fiber performance include length (the size of the longest dimension of the fiber), width (the size of the shortest dimension), and curl. These geometric attributes can significantly impact the properties and performance of fibrous materials, making precise measurement essential. However, many traditional particle sizing methods face challenges in accurately capturing these important morphological details.

Conventional volumetric-based particle sizing techniques, such as laser diffraction and Coulter Counters, operate under the assumption that particles exhibit a spherical geometry. Consequently, these methods report measurements as an equivalent spherical diameter (ESD), which fails to capture the true shape and structure of non-spherical particles like fibers. On the other hand, manual microscopy remains the standard method for measuring fiber length and width, but it is a low-throughput, labor-intensive process that is prone to variability and human error.

FlowCam: A Breakthrough in Fiber Analysis with Flow Imaging Microscopy

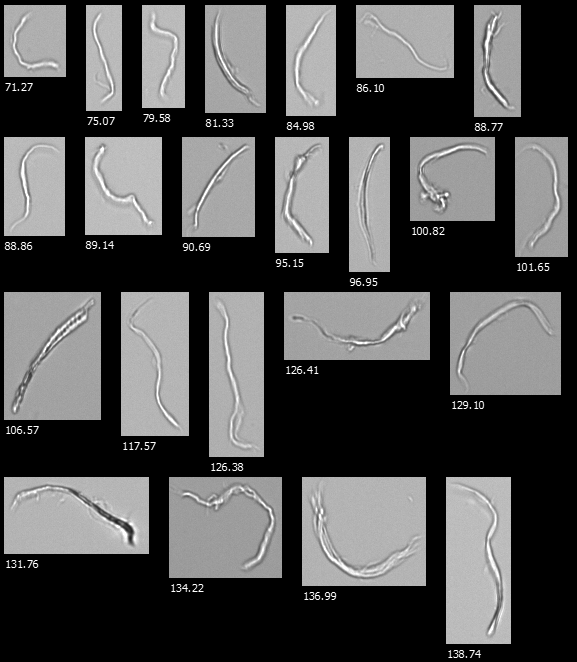

To address these limitations, our newly published technical note, Fiber Analysis with Flow Imaging Microscopy, introduces a novel approach to fiber characterization. This note reviews the definitions of Feret measurements for length and width, comparing them to Geodesic Length and Geodesic Thickness, two advanced metrics that more accurately describe fiber dimensions. It highlights how FlowCam, a flow imaging microscope, uses these Geodesic measurements, along with parameters for fiber straightness and curl, to provide a comprehensive and precise analysis of fiber size and shape.

FlowCam’s ability to analyze fiber morphology in detail is particularly valuable for applications where fiber geometry is a critical quality control parameter. For example, in industries such as textiles, construction, advanced materials, and even environmental monitoring, the physical properties of fibers can directly influence product performance and reliability. By leveraging FlowCam’s software, VisualSpreadsheet, users can build and save custom filters to automate the analysis of fiber characteristics. These filters allow for rapid, high-throughput reporting of counts and concentrations of fibers that meet specific criteria. For instance, if fiber straightness is a key concern, pre-built filters can be configured to automatically calculate and report the percentage of fibers that meet or exceed a user-defined straightness threshold.

Beyond these capabilities, FlowCam offers significant advantages in terms of efficiency and reproducibility. Unlike manual microscopy, which requires meticulous effort and can vary between operators, FlowCam delivers consistent results with minimal user intervention. Its high-throughput design enables the analysis of thousands of fibers in a fraction of the time required for manual methods, making it an ideal solution for routine quality control and research applications.

The insights provided by FlowCam’s advanced fiber analysis tools not only enhance our understanding of fiber morphology but also empower industries to optimize their processes and ensure product quality. Whether you are working with natural fibers, synthetic materials, or specialized fibrous composites, FlowCam offers a powerful and reliable solution for comprehensive fiber characterization. To learn more, download our technical note, Fiber Analysis with Flow Imaging Microscopy, and discover how FlowCam can help you achieve precise and efficient fiber analysis.