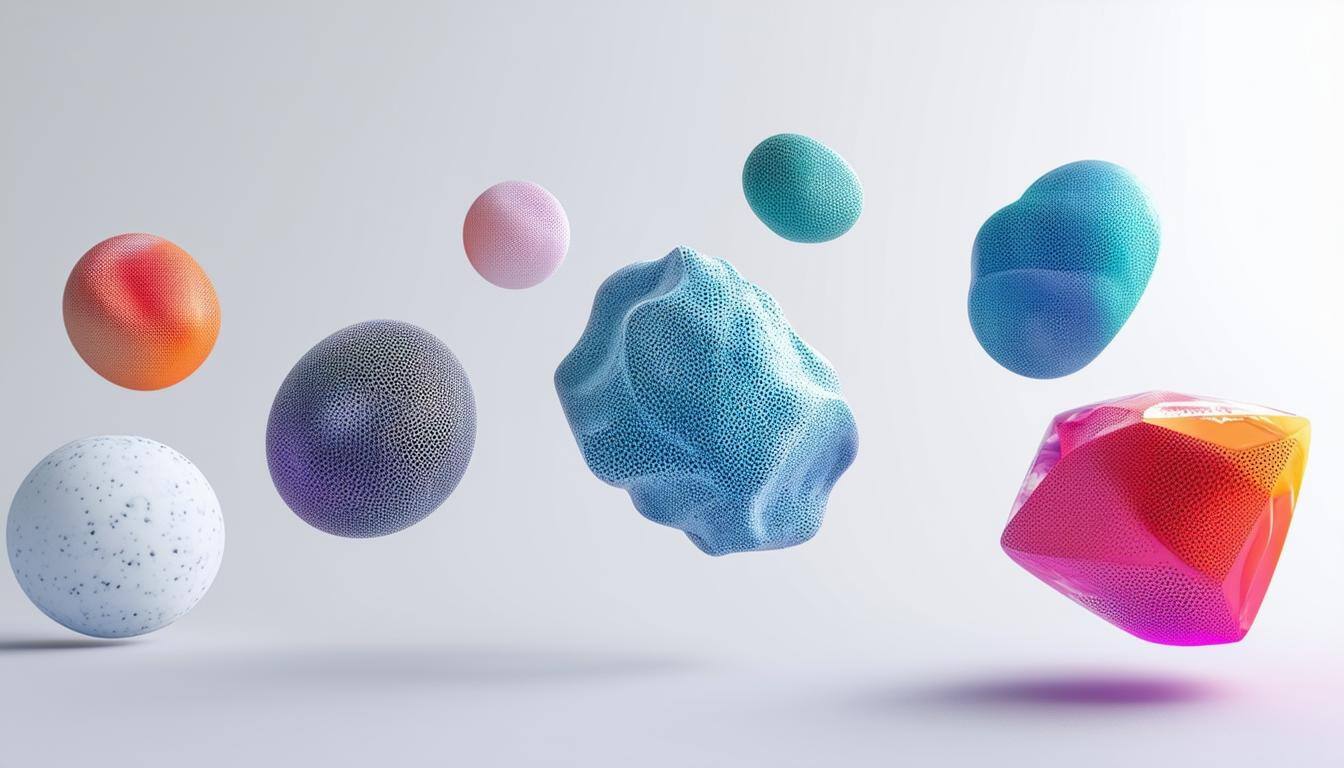

Particle characterization plays a crucial role in fields like pharmaceuticals, environmental science, and material engineering. While particle size has traditionally been the primary focus, particle shape is increasingly recognized as a critical factor influencing material behavior and product performance. Understanding the implications of particle shape can lead to more precise control over material properties, enabling innovations across industries such as printer toner, food & beverage, pollen, seeds, soils, advanced materials and others.

Beyond Size: The Limitations of Traditional Methods

Traditional particle analysis methods, such as laser diffraction or dynamic light scattering, often rely on the assumption that particles are spherical. While this simplifies measurement, it does not reflect the real-world complexity of particles, which can exhibit a wide range of shapes. Ignoring shape risks an incomplete understanding of how particles interact in different environments and applications.

The shape of a particle can influence its behavior in significant ways, impacting multiple material properties, including:

- Flowability: Irregularly shaped particles increase surface area and friction, which can hinder flow. This is particularly important in industries where efficient material handling is essential, such as pharmaceuticals and agriculture.

- Packing Density: Non-spherical particles pack less efficiently, resulting in lower density and less stable suspensions. This can influence the texture and stability of materials like paints, coatings, and powders.

- Dissolution Rate: Particle shape directly affects the surface area exposed to a solvent, altering how quickly a material dissolves. This has significant implications in drug formulation, where dissolution rate can affect drug release and bioavailability.

- Bioavailability: In pharmaceutical contexts, the shape of drug particles can alter how the drug is absorbed in the body, potentially improving therapeutic outcomes.

- Product Appearance and Texture: Particle shape also affects consumer products' visual and tactile properties, from food to cosmetics, where appearance and feel are often key differentiators.

Evolution of Particle Shape Analysis

The significance of particle shape has long been understood. As early as 1963, geologists used the Krumbein scale to visually assess the roundness and sphericity of sediment particles. While effective for rough estimations, this method was subjective and labor-intensive. The advent of microscopy improved shape analysis, but it remained limited by its low throughput.

The 1990s marked a turning point with the introduction of automated image analysis, made possible by advancements in machine vision and computational power. These technologies allowed for high-throughput, objective, and precise shape characterization, providing a wealth of data that size-only methods could not.

Today, shape analysis has evolved into a complementary technique alongside traditional particle size analysis. These methods provide a more comprehensive picture of a material's properties, opening the door to new possibilities in material design and product development.

FlowCam: Advancing Particle Shape Characterization

FlowCam technology is at the forefront of particle shape characterization. It uses flow imaging microscopy (FIM), also known as dynamic image analysis (DIA), to capture high-resolution digital images of particles in a fluid medium, delivering detailed data on both particle size and shape.

Here’s why FlowCam is a preferred tool for particle shape characterization:

- Comprehensive shape and size analysis: FlowCam analyzes over 40 morphological parameters, capturing intricate details about particle shape that go beyond mere size measurements. This allows for a deeper understanding of particle behavior, which is critical in industries like biopharmaceuticals, where shape affects drug delivery and efficacy.

- High-throughput capability: FlowCam can process up to 50,000 particles per minute, providing rapid, statistically robust data. This high throughput is essential for industries that require quick, reliable analysis, such as environmental monitoring or industrial quality control.

- Visual confirmation: FlowCam's high-resolution images offer visual confirmation of particle morphology. Researchers can quantify shape characteristics and directly observe particle structures, enhancing data interpretation and accuracy.

- Automated particle identification: Optional AI-powered software further enhances the FlowCam’s utility by automating particle identification based on morphology. This streamlines workflows and improves precision, especially in complex biological and industrial samples.

- Application-specific solutions: FlowCam instruments are tailored to various applications, including aquatic research, pharmaceutical development, and materials science. This versatility makes them ideal choices for any industry where particle shape plays a critical role.

Interested in Particle Shape Analysis?

In particle characterization, size is no longer the only story. As technologies like FlowCam demonstrate, particle shape profoundly impacts material properties and product performance. Embracing shape analysis enables industries to gain deeper insights into their materials, optimize processes, and develop innovative products.

To learn more about the power of particle shape analysis, refer to our Ultimate Guide to Flow Imaging Microscopy.