![]() The team at the University of Colorado, Boulder have long been FlowCam customers, most recently incorporating FlowCam images with artificial intelligence, in the form of convolutional neural networks, to characterize and identify impurities in protein therapeutics and cell based medicines.

The team at the University of Colorado, Boulder have long been FlowCam customers, most recently incorporating FlowCam images with artificial intelligence, in the form of convolutional neural networks, to characterize and identify impurities in protein therapeutics and cell based medicines.

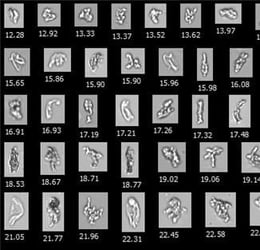

Given that aggregation is a major challenge in the manufacture of therapeutic proteins, it continues to be important to identify the numerous stresses encountered during protein production, and which are most likely to cause aggregation. This ensuing analysis provides a quantitative method to determine what kinds of stress conditions (freeze-thawing, interactions at air-water and container-water interfaces, exposure to excipient degradation products, elevated temperatures, and the use of glass versus plastic tubes/vials) resulted in protein aggregation.

The root cause of protein aggregation can be elusive. However, the various stresses that promote protein aggregation do so by different molecular mechanisms. Images recorded with flow imaging microscopy (FlowCam) can demonstrate unique characteristic morphologies or fingerprints, which can be traced to different stress conditions during their manufacture, shipping, storage and patient administration.

Read the paper here to learn more about their methodology:

Machine learning and statistical analyses for extracting and characterizing "fingerprints" of antibody aggregation at container interfaces from flow microscopy images.

Austin L. Daniels, Christopher P. Calderon, Theodore W. Randolph