It is no secret that plastic has found its way into more and more everyday products. However, it may be surprising to learn about the sheer volume of plastic particulates shedding from these products and being released into the environment on a daily basis.

In many everyday products containing plastics, tiny particles are being shed into the environment by various means; either mechanical or thermal or other. Not only do these particulates have a long life cycle, but they degrade very slowly in our ecosystem. The impact of ingesting microplastics on human health has not been well documented.

A recent paper published in Analytik News discusses the use of the FlowCam imaging particle analyzer to detect and measure plastic particulates shedding from various brands of plastic and glass electric water kettles. This study examines the susceptibility of the plastic in the different kettles to thermal degradation.

In this study, 4 plastic kettles from different manufacturers (Emerio, Philips, Braun, OK) and one glass kettle manufactured by Ciantronic were cleaned and filled with particle-free water which was then boiled. Samples of water were taken from each kettle after various sequences of boiling and cooling, and analyzed in the FlowCam imaging particle analyzer.

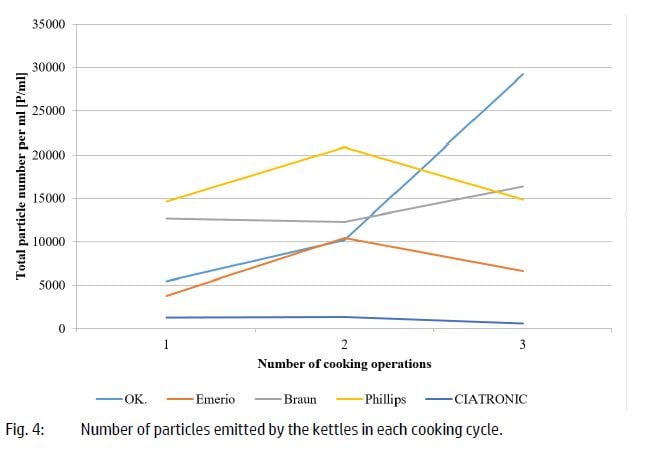

While different levels of particulates were measured from each of the plastic kettles, the results of the test show a significantly higher particle generation rate after boiling the water in plastic-based kettles compared to the glass kettle. Of particular interest is the change in number of particles emitted by the kettles in each cooking cycle over time.

Based on the test results it can be concluded that micro particulates are shedding from the plastic kettles over time. The resistance to degradation will depend on the chemical composition of the plastic polymer in use. Polymers such as polyethylene (PE) and polypropylene (PP), those used in the tested water heaters, are very susceptible to thermal degradation, and can only withstand thermal degradation when formulated with UV stabilizers and antioxidants.