Recent studies have shown that knowing the actual length and width of particles in chemical formulations can be of critical importance to product effectiveness.

FlowCam gives you this information instantly – providing you with an accurate size distribution, shape information, and a digital image of each particle.

You can use the FlowCam to maintain quality control in a variety of chemical mixtures, including paint and coatings, printing ink and ink jet toner, consumer products, such as detergents and shampoos, adhesives, as well as emulsions and mixtures.

Some examples of how the FlowCam can be used in the Chemical Industry Include:

- Controlling quality of chemical mixture

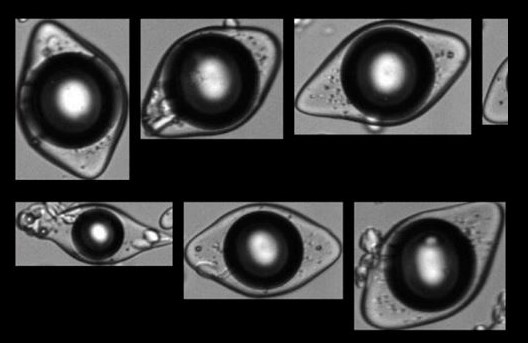

- Optimizing the microencapsulation process

- Characterizing column packing material in chromatography

Pictured above: Microencapsulations imaged and analyzed by the FlowCam imaging particle analyzer

Example: Quality Control of a Solvent-Based Chemical

A solvent-based chemical used in the production of a globally available consumer product required a specific ratio of solid black specks dispersed throughout the opaque liquid. If a sample lacked the proper ratio of particulates, the entire batch was discarded. With production humming in quantities measured by the metric ton, each bad batch could cost thousands of dollars. But more alarming to the quality assurance team was the potential for a bad sample to slip through testing, earn approval and ship to a customer. Once there, a bad batch would manifest itself in a variety of costly production woes that would ultimately be traced back to the quality of the chemical.

To determine whether each batch sample contained the proper amount of particulates, the company relied on a manual inspection system combining traditional microscopes and the naked eye. But making slides and grabbing images of every particle of every batch was time consuming, labor intensive and impractical at best, if virtually impossible. With the FlowCam, they are able to automate and accelerate the entire testing process.

Using the FlowCam they determine the length, width, and opacity of each particle and then characterize, document and archive each one for further analysis. In a few seconds, the FlowCam can image as many particles as a skilled lab technician with a standard manual microscope can image in a week, and with finer resolution and superior detail. Plus, the use of the FlowCam also reduces chemical handling and minimizes exposure to staff and the environment.

With their library of visual, tangible knowledge, the quality assurance team can now quickly email the images to manufacturing and help pinpoint the root cause of a process interruption while providing a common basis for the discussion. The speed and certainty of documenting the culprit particles saves time, reduces waste production and ensures peak material quality.

The FlowCam provides them with an amazing insight into the entire process that has provided a level of understanding that just could not happen with any other technology. The company established a new set of batch testing criteria based on the unique abilities of the FlowCam.

Interested in learning more? Download the FlowCam 8000 brochure, and visit our Materials Applications page to download brochures for all FlowCam imaging particle analyzers, read case studies, and more.