Microalgae present a viable alternative to crude oil for the production of renewable fuels suitable for land, marine, and air transportation. This is achieved through the utilization of either accumulated lipids or biomass hydrocarbons. A significant advantage of algae-based biofuels is their ability to be produced without the extensive use of fresh water and arable land, which are critical resources. Additionally, microalgae serve as a source for producing animal feeds, fertilizers, food, and various other chemicals that are traditionally derived from crude oil.

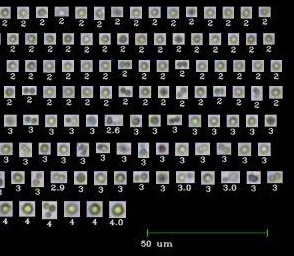

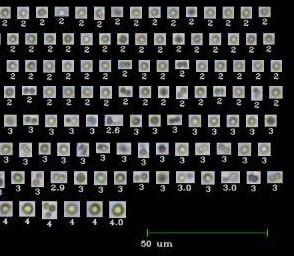

Microalgae cells are notably small, typically measuring between one and ten micrometers, and they thrive in highly diluted water environments, approximately 1 gram per liter. These characteristics contribute to the elevated costs and energy demands associated with microalgae processing, which is currently highly resource-intensive and not feasible for large-scale production. A key challenge is that the substantial volumes of water involved necessitate significant energy for both pumping and dewatering processes.

Centrifugation, chemical coagulation, and electrocoagulation flocculation (ECF) using batch reactors are a few examples of existing harvest processes. These methods require high energy input, large amounts of chemicals, and/or additional infrastructure such as settling tanks.

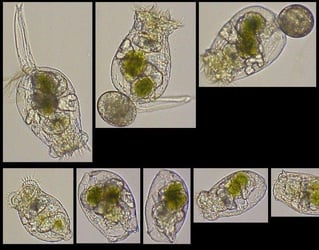

Right: From the Fluid Imaging Technologies lab- Nannochloropsis at 20X.

FlowCam has been implemented as an important tool in the cultivation and monitoring of microalgae. Keep reading to learn about a new method for harvesting microalgae.

A study from Seattle University and Utah State University (Shuman et al., 2016) examined the effects of pre-concentrating Nannochloropsis sp. using a continuous flow method of ECF instead of a batch reactor ECF. Water was pre-treated with direct current and then applied to algae at pond concentrations at various flow rates. The ECF process and its effects on cell viability were observed during the study using a FlowCam.

This study describes a process where saltwater is treated using a continuous flow process and then mixed with marine microalgae Nannochloropsis sp. in their growth medium to induce biomass separation from the liquid. The advantage of this approach is that the expensive processing equipment, including electrodes and control electronics, is only used in treating saltwater. This increases equipment lifetime and substantially decreases cleaning costs.

This study introduces an innovative technique that involves exposing a flowing fluid to direct current for a brief duration, ranging from 0.8 to 7.5 seconds. This exposure facilitates the rapid separation of algae, occurring approximately 30 minutes following the ECF treatment. It is important to note that the fluid flow rate inversely affects ECF Efficiency when compared to batch tests. The highest ECF Efficiency observed in this research was 92% at a flow rate of 0.4 L/min and a voltage of 7 V using nickel electrodes. Higher voltage inputs and reduced flow rates enhance ECF Efficiencies.

However, the optimal ratio of ECF Efficiency to energy input is achieved with the lowest voltage inputs and highest flow rates. Specifically, treatments with a flow rate of 3.9 L/min and 6 V yielded the highest ratio of ECF Efficiency to energy input, measuring 151 and 406%/(kWh/m3) for nickel and aluminum electrodes, respectively. The ECF process effectively separates a substantial number of viable algal cells from their growth medium, with a separation rate of 40–60% under the studied conditions. Furthermore, metal analysis reveals that post-ECF treatment with nickel and aluminum electrodes at 8 V and a flow rate of 0.8 L/min, the microalgae absorb significant amounts of metal, specifically 348.6 ± 66.7 mgNi/g dry biomass and 125.2 ± 15.2 mgAl/g dry biomass.

Are you curious to learn more about FlowCam applications? Visit our page for algae viability analysis.

REFERENCES

Shuman, T.R., Mason, G., Reeve, D., Schacht, A., Goodrich, A., Napan, K., Quinn, J. (2016) Low-energy input continuous flow rapid pre-concentration of microalgae through elector-coagulation-flocculation. Chemical Engineering Journal, 297, 97-105.