Particle analysis is a critical but often tedious task for researchers in analytical laboratories. Data collection is not only time-consuming but can involve additional sample handling steps that introduce inconsistencies to the final measurements. Automation provides a natural solution to these issues, and automated liquid handlers (ALH) use robotics to perform sample processing enabling analysis with minimal human intervention. Automation not only vastly reduces the time and effort required from operators to perform experiments but, in the context of analytical instruments, helps users collect more reproducible and overall higher quality data.

Learn about the key benefits of adding automation to flow imaging microscopy and how these are implemented in ALH for FlowCamTM below.

1. Automation Increases Productivity

Analysts are responsible for a variety of laboratory tasks beyond data collection and sample preparation, such as experiment design, data analysis, collaboration with other researchers, etc. Relative to these “higher-level” tasks, researchers can find data collection and sample preparation time-consuming and highly repetitive. Robotic handling allows for unattended operation and supports analysis protocols that can be developed to automatically preprocess and analyze multiple samples while the researcher pursues other tasks.

2. Automated Operation Improves Repeatability

Analytical instrument measurements often involve several sample handling steps such as mixing, heating, cooling, and injecting samples into the instrument. Each manual step may introduce inconsistencies to the analysis that can influence the results.

These variabilities can mask the underlying differences between samples. Biotherapeutics are especially prone to this effect as common sample handling steps like mixing and dilution can influence factors like particle content if not performed carefully. Automating sample handling steps can result in more reproducible and overall higher quality data from the instrument that can be invaluable in many research contexts and applications.

3. Flexible Hardware and Software Adapt to User's Needs

Successful integration into an existing workflow depends primarily on the flexibility of the automation hardware and software. Factors such as the size and options of the sample deck layout will determine the number of samples and the types of processing steps that can be automated. Similarly, automation software should allow users to develop automated protocols that utilize all of the functionality of the liquid handler.

4. Integrated Software Provides Ease of Use

Operators can readily integrate automation into their protocols if the automation hardware and software are easy to learn and use. While researchers developing analytical protocols benefit from a powerful interface with access to all functions on the instrument, users performing routine analysis may prefer a streamlined user interface that lets them analyze samples with a single click of a button. Ideally, liquid handling software will accommodate all user preferences.

5. A Complete Solution Enables Maximum Productivity

Long-term success with automated analytical measurements depends not only on the automation instrument setup and integration but also on system maintenance and service. Therefore, it is important that the vendor of an integrated solution can provide comprehensive after-sales service and support for the entire setup. These services can help maximize uptime and overall productivity.

Conclusions

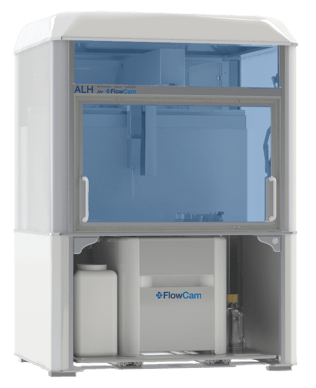

Automating sample analysis enables significant productivity and quality improvements that benefit both users and lab operations. FlowCam's automation solution, ALH for FlowCamTM, streamlines data acquisition as well as sample preparation steps including mixing and diluting. It offers a variety of hardware and software tools to implement custom analysis schemes that ensure that every step is performed consistently, resulting in high-quality data.

ALH for FlowCam is configured to provide easy-to-use software integration regardless of a user's experience and requirements. The software allows for several possible workflows ranging in complexity from push-button operation to full customization of sample analysis.

Unattended FlowCam operation can offer significant cost savings while offering higher quality data and increased lab productivity by freeing up researchers to pursue more complex tasks. The flexibility and ease of use of ALH for FlowCam make it straightforward for users to add automation to an existing FlowCam instrument and tailor the automation to the user’s existing workflow. Learn more by downloading the brochure.